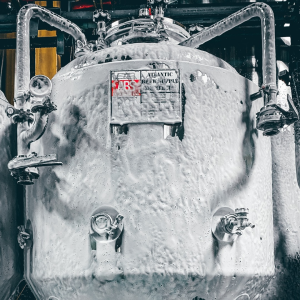

Your brewery equipment is an investment and should be treated that way. While stainless steel can withstand a lot, it is not indestructible. Like all equipment, it still will experience wear and tear and needs to be properly taken care of to make sure it is working as efficiently as possible and can last as long as you need it to. At ABS Commercial, we pride ourselves on being your trusted, full-service brewery outfitter and helping you set up and keep your brewery equipment in peak condition.

Just Setting Up

Even with new equipment, there are tasks to complete to set yourself up for success and have your stainless steel last. If not properly treated, stainless steel can corrode or rust, so it needs to be passivated. Passivation is a metal finishing process to prevent corrosion using an acid solution to remove free iron from the surface. The chemical treatment leads to a protective oxide layer, that is less likely to chemically react with air and cause corrosion. Passivated stainless steel resists rust and helps extend its life.

When receiving new equipment, it is recommended to clean using a degreasing agent, passivate, and sanitize before use, even if the manufacturer says the equipment comes already passivated. You want to be in control of the process and know it has been done to your standards. Stainless steel should be re-passivated every year as a preventative measure, or anytime you believe the protective oxide layer has been damaged (stubborn stains that required you to scrub excessively, any scratches, nicks, or dents to the stainless, exposure to regular steel, steel wool, or iron metals, exposure to bleach cleaners, and with unique water quality i.e. hard water or RO water).

Along with passivation, new equipment should also be checked for leaks by running a full test cycle with water. Tanks and equipment that hold pressure should also be tested to ensure they can hold and maintain pressure.

Ongoing Care

Ongoing cleaning practices ensure the quality of your final product and keep your equipment well-maintained. Set up a Clean-In-Place (CIP) process for cleaning and sanitizing your equipment. Your team should be consistent and follow the same process and protocols. There are numerous brands of CIP chemicals on the market and it’s important to understand the chemicals you are using and follow the correct guidelines from your chemical supplier. Temperature, pH, dosage rate, dilution, cycle time, and interaction with other chemicals and CO2 all play a part in how effectively your tanks will be cleaned.

Alkaline cleaners, both caustic and non-caustic, work to clean organic material, like wort, yeast, and hop residue. Acid cleaners work on non-organic materials, like water scale, beer stone, and other mineral build-ups. Sanitizers prevent contaminants such as mold and bacteria from growing on equipment but only work on equipment that has been properly cleaned, rinsed, and dried. If sanitizing parts, put parts back on the equipment wet to create a sanitary seal.

In addition to cleaning and sanitizing your brewery vessels, it’s also important to clean and sanitize all small parts and the ports they are connected to. Carb stones, gaskets, manway gaskets, clamps, etc. should be removed and cleaned. This allows you to deep clean those individual pieces, check them for wear and tear, and replace them if needed. This should also include secondary containers (buckets, pitchers, graduated cylinders, measuring cups), and hand tools (wrenches, pliers, brushes) after their use. These pieces move around the brewery and can potentially cross-contaminate other equipment. Rubber hoses are also prone to cracks, wear spots, and holding onto moisture that can breed bacteria and should also be cleaned, purged, and sanitized.

Use non-abrasive scrubbers and brushes while cleaning the brewery equipment – inside and outside the vessels. Abrasive scrubbers can scratch the stainless steel, which puts the equipment at risk of being contaminated. Just like with a CIP process, schedule routine cleanings of exterior surfaces. This will prevent mineral buildup from CIP chemicals and biofilm and keep your tanks looking shiny.

Stay Ahead with Preventative Maintenance

We know that wear and tear is normal on any piece of equipment. Regardless of brewery size, regular brewery maintenance ensures that your brewing operations run smoothly.

Being proactive with a preventative maintenance routine for your brewery saves a myriad of potential headaches: permanent damage to equipment, spending more money to get equipment fixed immediately, frustrated brewery staff, missed deadlines for beer sales, quality control issues, and safety and liability issues. When your equipment is cared for correctly, it will do its job the same way each time, resulting in a more consistent and quality-controlled product. Plus, maintaining your equipment will always be cheaper than replacing it.

Like with a CIP process, create a clear maintenance plan for everyone to follow. Set up a calendar with routine maintenance checks, ongoing cleaning and organizational tasks, and larger projects to tackle. Log this information to track your maintenance history and share it openly with the team. Keep instructions and manuals all in one place for easy access. It’s also important to understand what tasks your team can do themselves and what tasks need to be outsourced to a professional. For outsourced tasks, have a go-to list of companies that you know and trust.

Our article Set Yourself Up for Success with Preventative Maintenance, dives deeper into a full checklist of equipment to check and tasks to tackle as part of your preventative maintenance schedule.

A clean and organized production space will make it easier to complete maintenance tasks. Create a spare parts management system to label and track parts and pieces and note quantities. Know when and how often certain equipment needs maintenance to keep parts on hand ahead of time. These parts can be classified based on importance. Critical spare parts should always have enough inventory in-house to replace directly when needed. General spare parts should be easy to get ahold of when needed (always in stock with your supplier, quick delivery time). Non-critical spare parts are acceptable to have a longer lead or delivery time.

Keep your inventory simple and standardize the number of different brands/models used, when possible. This will help consolidate suppliers, save on shipping costs, and over time help understand the quality and lifespan of certain parts.

These are items recommend always having on hand in your production space:

- TC Gaskets in all sizes

- Manway gaskets

- Carb stones

- Pump seal & gasket replacement kits

- Butterfly valve seats

- Glycol and steam valve replacement parts

- PIDs for control panels

- Hose clamps/crimps

- Food-grade lubricant

Our team at ABS Commercial stems from years of technical brewing experience. We know the ins and outs of the brewing process and we approach everything from the mindset of the brewer. We have spent the last 10 years continuously improving our equipment through in-house testing at our sister company, Raleigh Brewing Company, as well as through hundreds of installations around the country. Have questions or running into issues? Contact our tech support team for help.

As brewers, we understand the importance of keeping your equipment running smoothly and efficiently. Our ABS Small Parts Shop offers a wide range of brewhouse accessories, small parts, consumables, and wear items. We also offer Wear Item Kits like our Tri-Clamp & Silicone Gasket Kit and Brewhouse & Fermenter Gasket Kit, making it easy to purchase the wear items you need in bulk, and at a more affordable price. We want to ensure that you can find the items you need when you need them so that you can get back to what is most important—operating your brewhouse.